The Process of Casting Glass

Welcome to the world of glass casting. The process of making a glass sculpture is a mysterious one for many people. For the artists in glass, they know it is a pure labour of love. I want to bring you on a journey with me through the process of making Potential and give you a little peek of what it’s like behind the scenes.

Sit back and join me on a long ride, this project actually took me 9 months to fully realize from beginning to end!

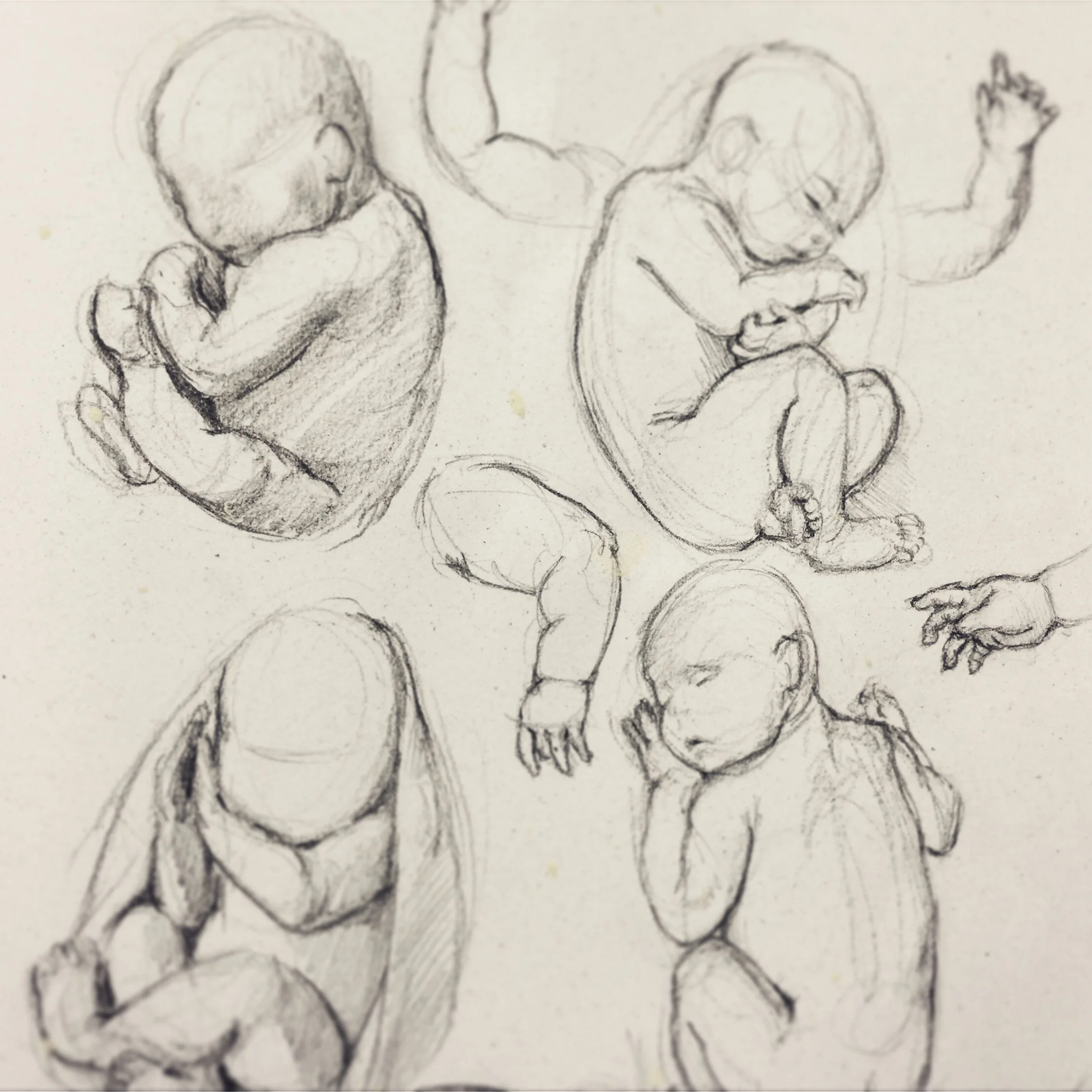

Conceptualizing

In order to understand the my subject more, I like to start off with some detailed and rough sketches to give me insight into what feelings the forms could evoke.

Clay Sculpting

I finalize the form by making my sketch into a 3 Dimensional reality. This clay sculpture isn’t mean to be kept though, I often end up destroying the clay positive in the process.

Silicone Mould

In order to make wax positives of my clay sculpture for the lost wax process, I have to first create a silicone master mould. It’s also smart because there’s a high chance I might have to restart the process if the firing process fails.

Demoulding

Wax Positive

To create the wax positive, I fill up the silicone moulds with hot liquid wax. This is the part where I need to make sure I get the details right, as any flaws in the wax will appear in the glass and glass is a much harder material to fix. Literally.

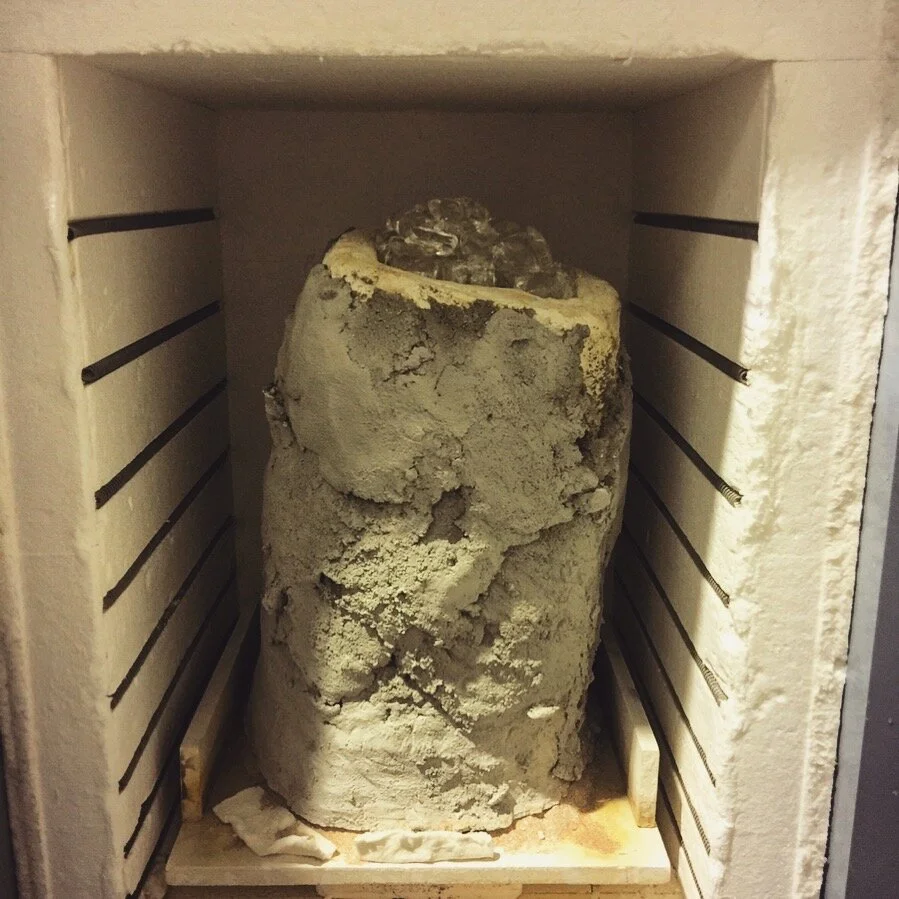

Investment Mould

This is the mould that goes into the kiln. It needs to be able to withstand temperatures as high as 890°C (1634°F) for an extended period of time as glass slowing makes its way into all the crevices.

The wax positive gets steamed out before the firing starts, leaving a clean hollow mould.

Firing

The glass will usually be in the kiln melting into the investment mould for a minimum of 7 days. This is due to the slow annealing which is necessary to take the stress out of the glass while cooling. The thicker the glass the longer the annealing time.

Fun fact: The Lens for the Hale telescope is the thickest object to be cast in human history, it’s 200 inches thick (5.1m) and it took a full 10 months to anneal.

Divesting

This is the most exciting part of the process! (If it worked, most heartbreaking if it didn’t haha) This is the part where you find out if the cast was a success (there’s an average of 60% success rate in glass casting world wide). It’s like unwrapping a gift and finding out if the weeks or months of work paid off.

Sometimes you have to have multiple firings if your kiln isn’t big enough to handle it like me here.

Polishing

We’re almost done but we’re not there yet! Polishing is the last step and it sounds quite relaxing but I assure you, it is not! It can take weeks going over each detail, drilling off flaws and hand polishing every surface to get a refined finish. But it’s a step not to be missed!

When you’re an artist who works with a certain type of medium you develop a psychological bond with it. Many artists describe their choice as a calling from the medium, or an addiction. But I also see it as a reflection of the qualities within themselves. My choice of glass exists in its indomitable and wild nature, especially during its casting stages, but also in its sensitivity and transparency. When it’s hot it runs like honey, choosing its own path while you can only influence it subtly. When it’s cold it’s fragile, but beautiful and it takes careful attention to polish it properly. Every part of the process hones patience.

As an artist working with glass, I feel like it has shaped me as much I have shaped it.

You can read more about my very humble beginning with the process in this journal entry.